Automation for fashion customers

The system designed and implemented by Dematic at the Radial site in Groningen has made it possible to speed up order processing while significantly reducing error rates. Today, nearly 300 autonomous mobile robots (AMRs) support our e-commerce fulfillment operations for a well-known Dutch fashion brand. Read the interview with Ron Kleinsmit, Site Manager at Groningen, the Netherlands.

In this interview, Ron Kleinsmit, Groningen Site Manager at Radial, discusses the collaboration with Dematic, a provider of advanced automation technology. Dematic’s integration of cutting-edge robotics and AI technologies into warehouse operations has been instrumental in driving efficiency gains, enhancing flexibility and scalability, and optimizing both employee and customer experiences for Radial.

Automating the warehouse: key drivers

Joanna: Hello Ron. Could you tell us what factors were behind the decision to automate the warehouse in Groningen?

Ron: Hello. Radial facility in Groningen is one of the seven facilities throughout Europe. We are a fulfillment business partner for a lot of B2C e-commerce businesses. That is what we are focusing on.

Going from manual to automated operations begins with understanding the market requirements, particularly in e-commerce, where fulfilling orders “on time in full” is crucial. This means having late cutoff times for customers to place orders, often extending into the evening, with the expectation of delivery within 24 hours.

Given the high volatility in both volume and the variety of SKUs (Stock Keeping Units) or different items, relying solely on manual operations becomes insufficient. Optimisation becomes imperative to achieve the necessary high throughput.

- Late cutoff times

- Delivery within 24 hours

- High volatility in volume and variety of SKUs

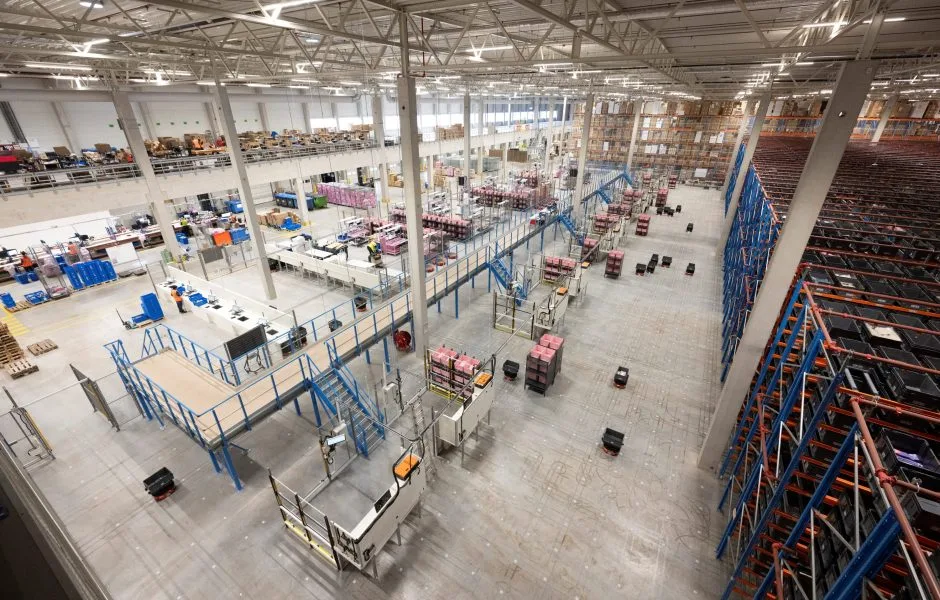

Radial’s distribution warehouse in Groningen, the Netherlands

Partnership with Dematic

Joanna: When you decided to automate the facility, you needed to select a partner to design and build the solution.

Ron: It’s about collaborating with people and working for people. We outlined our specifications and requirements, then explored the market to find suppliers who could assist us with this challenge. After a thorough search, we entered into a partnership with Dematic and Quicktrone to develop this excellent solution.

Joanna: What approach did you take towards implementing the solution designed by Dematic?

Ron: We could write a book about the implementation titled “This is a Success Story”. While I am fortunate to share it, the real credit goes to our exceptional team. The project manager, operations manager, and many others were critical to our success.

With a grand vision, we approached it incrementally, similar to running a marathon. Each step was manageable, allowing us to learn and adapt, embodying a scrum agile methodology. Customer involvement was minimal as we focused on maintaining and enhancing the flow.

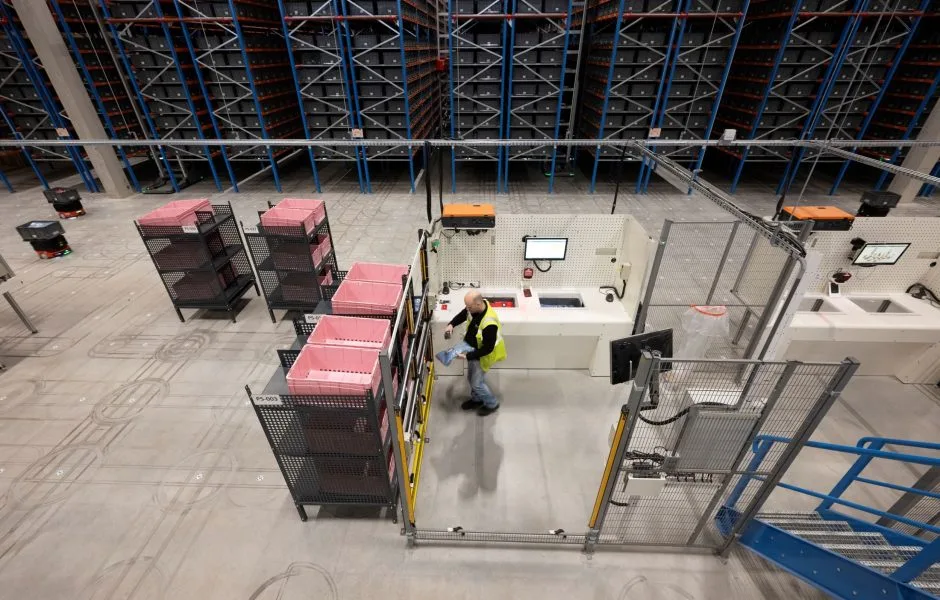

Tote Mover AMRs deploy swiftly and adapt to seasonality and scalability as needs change. It can transport materials in totes, remove waste, and perform non-value-added tasks.

Excellence factors

Joanna: What factors contribute to the excellence of this solution?

Ron: One of the key elements is its high adaptability. It allows us for high scalability. Should there be a need for changes, we can readily adapt. While the complexity lies in the algorithm and system, the process remains simple. It’s easy to operate, understand, and instruct others. People quickly learn the process

This enables us to handle high volumes and meet our customers’ demanding requirements. Our commitment to delivery was a critical factor in our decision-making, ensuring we could fulfil promises to our customers.

Joanna: Is this system specifically tailored for a single customer or designed to serve multiple clients?

Ron: The system Dematic designed and implemented can accommodate numerous customers, offering flexibility regardless of whether there are few or many SKUs and varying turnover rates. Currently, it caters to a fast-fashion customer, where new collections and a significant number of SKUs are introduced every couple of months. This influx of new data seamlessly integrates into the process.

- High adaptability

- High scalability

- Easy to operate, understand, and train

- Can accommodate numerous customers

- Flexibility for any SKU count and turnover rates

AMR tote movers streamline operations at the order picking station by efficiently transporting items

Balance between people and robots

Joanna: Does throughput emerge as the most crucial factor when comparing this solution to manual operations?

Ron: This solution allows us to process a high volume of orders per hour, a feat impossible to achieve manually. However, aiming for complete 100% optimisation isn’t necessarily optimal. Our goal was to strike a balance between automated and manual processes, and I believe we’ve achieved that.

We optimise operations by incorporating human operators and fine-tuning processes. People contribute intellect, effort, and experience. A 100% manual process wouldn’t meet the market’s demands, and a fully automated approach is neither optimal nor aligns with Radial’s values.

We value people and recognise their indispensable roles. Ultimately, the individuals behind the processes and the company genuinely matter. This belief is fundamental to us.

A 100% manual process wouldn’t meet the market’s demands, and a fully automated approach is neither optimal nor aligns with Radial’s values.

Order pick station in the distribution warehouse in Groningen, the Netherlands

Successful results

Joanna: What were the key factors that contributed to the success of this project?

Ron: At Radial, we believe in leveraging people’s knowledge, using common sense, and making swift decisions rather than delaying. With a stellar project manager, clear project descriptions, and prioritised focus, we made rapid, decisive decisions.

While our calculation department provided the data, our intuition and experience also played crucial roles. Some decisions that could have taken months were made in minutes, with the flexibility to backtrack if necessary. This fast and decisive approach was pivotal to our success.

Joanna: How would you summarize the results achieved through this solution?

Ron: We’ve achieved several notable results. Firstly, the solutions are remarkable and make people excited, like a child in a toy store. This aligns with Radial’s ambition to become a showcase for our partners and staff. Secondly, the throughput is impressive, showcasing our adaptability and continuous learning. We’ve paid our learning fee and now reap financial benefits.

Moreover, the ergonomic aspects ensure a manageable workload for our team, contributing to sustainability with minimal waste in the process. Most importantly, we can meet our customers’ needs efficiently. It’s crucial to emphasise that success isn’t solely attributed to automation but to the comprehensive, holistic approach.

The AMR tote mover picks up the tote

Future-proofing ecommerce fulfillment

Joanna: Sustainability is an essential factor in the fulfillment industry. How do you approach this challenge?

Ron: Sustainability is ingrained in our DNA and guides our broad approach. Our warehouse, certified with BREEAM, reflects our commitment to the highest standards. We continuously monitor sustainability and prioritise lean principles for continuous improvement. Our focus is on creating a wasteless operation, considering both material and talent utilisation. We are also mindful of our impact on future generations and remain dedicated to our purpose.

Joanna: At the end of our conversation, please describe your vision for the future of e-commerce order fulfilment.

Ron: I’m a fan of the movie ‘Back to the Future’ with Michael J. Fox. Predicting the future is challenging, especially in today’s fast-paced world, where leaders can quickly become outdated. In the e-commerce industry, change is constant, and it’s essential to remember its impact on our planet and future generations.

To stay relevant, we must remain youthful in our mindset and listen to diverse perspectives from the market, suppliers, and our team. Adapting to survive is both challenging and exciting, and it should be enjoyable. Hopefully, in the future, we’ll achieve an even better balance between enjoyment, efficiency, and functionality.

Joanna: Thank you, Ron, for providing such insightful details on the project. The adoption of this semi-automated solution will be a significant step forward for our new ecommerce customers.

Radial’s distribution center with BREEAM certificate, Groningen

Ron Kleinsmit, Site Manager in Groningen, brings a wide range of skills and experience to the team. He founded Dreamflights, a company specializing in hot-air balloon flights. After successfully selling his company managed operations and procurement for an industrial bakery procurement agency. Later, he led operations at Portena Logistiek, eventually becoming CEO before its sale to Nedcargo in 2021. Following this, he focused on consultancy in the logistics sector. In 2023, he joined Radial Europe. Ron lives in Frisia with his wife and three children. When not coaching hockey or hitting on the slopes, he enjoys music, singing, and playing guitar.

Interested in our Groningen site?